GAS INTERLOCKING SYSTEMS

GAS INTERLOCKING SYSTEM installations

Commercial kitchen gas interlocking systems engineered to meet BS6173

Solid Fuel Appliances

With the new regulations in place and the ever growing popularity of solid fuel appliances this new interlocking system is designed to control your fans via communication with a CO monitor and Co2 monitor to make sure that your kitchen maintains a safe working environment.

We install only the best gas interlocking systems that come complete with a 3 year guarantee.

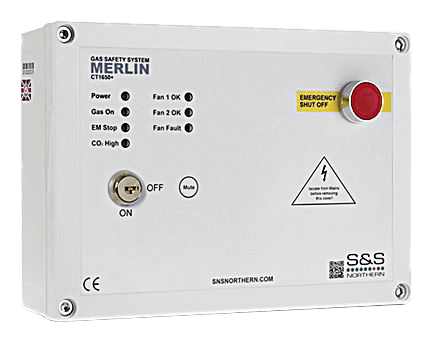

1650+ gas safety system

The Merlin 1650+ system displays the working current of the fans allowing the engineer to confidently and accurately calibrate the current monitors and interlock with the fans. The Merlin CT1650+ system acts as an interlock between the ventilation system and the gas solenoid valve. The Merlin CT1650+ system has built in current monitors to monitor the fans.

The current monitors can be calibrated to shut off the gas supply if the fan is working abnormally either below or above the fans normal current range. The 1650+ also has a built in 10% +/- threshold tolerance to eliminate nuisance momentary fan faults.

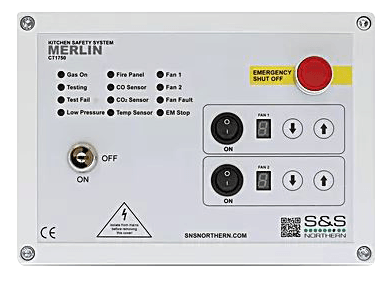

1750 gas safety system

The Merlin CT1750 system has two built in 0-10V dc outputs, this is designed to control fan controllers which will in turn increase the speed of a fans should any carbon dioxide or carbon monoxide detector that is connected to the panel goes into an alarm condition. The fans can also be controlled manually from the panel using the up & down buttons located on the panel fascia.

The Merlin 1750 has the facility for connection of a Merlin Carbon Dioxide detector. Should the CO2 detector go into an alarm condition a signal will be sent to the 1750 panel, the CO2 LED on the panel will light and the gas solenoid valve will close. The 1750 will automatically increase the fans to reduce the CO2 levels. The gas supply cannot be reinstated until the CO2 has reduced to an acceptable level.

If a gas solenoid valve is closed in a commercial kitchen that is fitted with standard gas ovens and grills the gas appliances will no longer give off dangerous gases such as carbon monoxide. However where solid fuel appliances such as charcoal ovens and grilles are installed there is a possibility that the coals will continue to smoulder and therefore produce harmful carbon monoxide even when the appliance is no longer being used.

If the detectors alarm due to higher than normal levels of gases being present in the kitchen, the fans will be instantly boosted to full speed, even if the Merlin CT1750 system is turned in the “off” position. Once the gases have been cleared, the fans will be shut down, ensuring the kitchen doesn't incur any unnecessary running costs.

REQUEST AN ENGINEER

To discuss a gas interlocking system installation, call Castle Catering Engineers Ltd in Nottingham.

3000s gas safety system

The Merlin 3000S system has 2 built-in 0-10VDC outputs. This is designed to vary the speed of the ventilation system(s) based on either, real-time gas usage via a turbine gas meter, carbon dioxide (CO2) levels in the area, smoke/steam detection in the canopy using optical sensors or heat detection in the extract duct work using a thermostat. For the best and most accurate results, all should be used together but any combination of the 4 sensors can be used.

As the CO2 or gas usage increases in the commercial kitchen, the Merlin 3000S will increase the speed of the ventilation system to provide the perfect cooking environment. Conversely, when only minimal gas is being used and the CO2 levels are low, the Merlin 3000S will reduce the speed of the ventilation systems, saving energy and money. The optical sensor will increase the ventilation should it detect excess smoke or steam in the canopy along with the duct mounted heat sensor to monitor excess heat in the duct. The Merlin 3000S also carries out its duty as a traditional ventilation interlock and gas pressure proving system alongside the ventilation on demand capabilities. This allows for one single small control panel in the kitchen, freeing up valuable real estate on the kitchen walls.

Contact Us

Unit 8 Pottery Court

Pottery Way

Nottingham

NG6 8YN

7 days a week 365 Days a year

In case of an emergency please leave a voice message and we will get back to you ASAP.

Contact us

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Uh oh, there was an error sending your message.

Please try again later

Please try again later

© 2024. The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.